2 and 3 way piston valve.

CHARACTERISTICS

- All or nothing valve.

- Perfect sealing with disc ring made of PTFE (polytetrafluoroethylene).

- Double stem structure that absorbs the impact on the seat.

- Body and lower seat flange made of stainless steel.

- Gland packing made of 4 pieces of V-packing that prevents leakage around the stem.

- Spring with shot-blasting process improves service life.

MODELOS DISPONIBLES

VP3W-FR

VP3W-SR

VP3W-FD

VP3W-SD

SPECIFICATIONS

| Nombre del modelo |

3-vías |

VP3W-FR(S) | VP3W-SR |

VP3W-FD(S) | VP3W-SD |

|---|---|---|---|---|---|

| 2-vías |

VP2W-FR(S) | VP2W-SR |

VP2W-FD(S) | VP2W-SD | |

| Fluidos | Vapor, Agua Industrial, Gas (N2), Aire, Vacío. | ||||

| Tamaño (mm) | 15A~80A | 8A~50A | 15A~50A | 8A~50A | |

| Operación | Normalmente cerrado (NC) | Normalmente abierto (NO) | |||

| Conexión final | Bridado | Roscado | Bridado | Roscado | |

| Material | Cuerpo, Brida del Asiento Inferior, Vástago: Acero Inoxidable. | ||||

| Flujo de Aire |

2.5 ~ 3.5 kg/cm2 (36~50psi) | ||||

| Temperatura | Máx.230°C (446°F) | ||||

| Presión | Max.32kg/cm2 (455psi) | ||||

| Prueba hidráulica del cuerpo | Max.48kg/cm2 (682psi) | ||||

a) JIS, DIN and ANSI standards are available.

b) (S) means stainless steel (SUS) flange.

c) To prevent flange cavitation, the user must use a stainless steel (SUS) flange.

d) The option is offered to block the third port with a plug or an under-seat flange.

e) The option without welding flange and without welded body is available.

f) Single stem type is available.

g) Available for high pressure (JIS 30K, JIS 63K).

h) Third port flange is available.

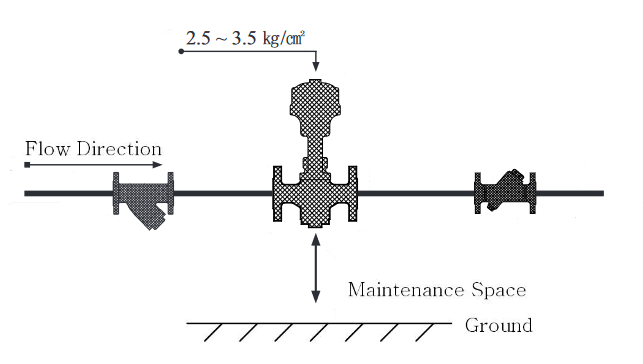

INSTALATION

a) The pipe should be cleaned by methods such as flushing with water before installing the valve.

b) A filter should be installed for good performance and long trouble-free valve life. Filters foreign materials in the pipe.

c) A check valve is installed to prevent reverse flow.

d) The pipeline must have enough space for maintenance of the third port in case of emergency.

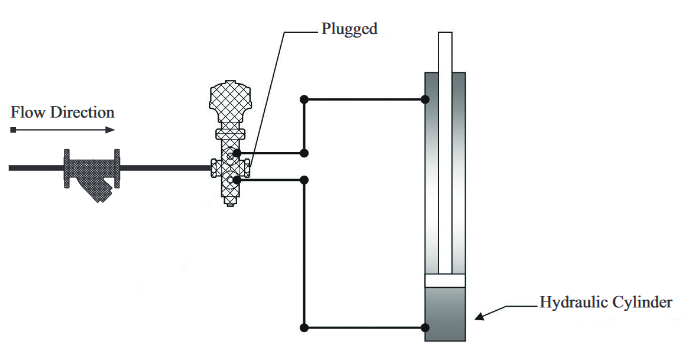

4-way piston valve.

CHARACTERISTICS

- The valve is connected to and operates a hydraulic water cylinder.

- Internal design to increase O-ring life.

- The valve can save the use of other valves.

AVAILABLE MODELS

V4010S-D

V4010S-S

V4020S-D

V4020S-S

SPECIFICATIONS

| Model name |

V4010S-S |

V4010S-S |

V4020S-D |

V4020S-D |

|---|---|---|---|---|

| Fluids | Industrial water | |||

| Size (mm) | 8A - 10A | 15A - 20A | ||

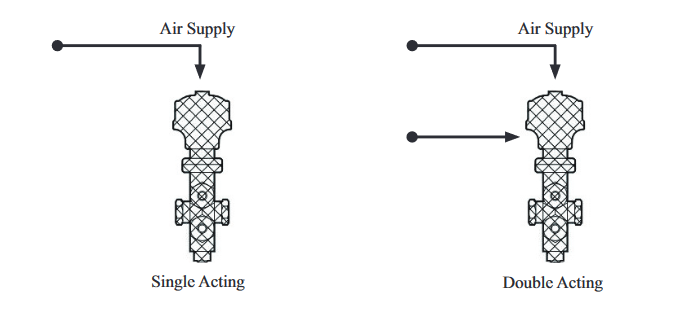

| Operation | Simple action | Double Action | Simple action | Double Action |

| Final connection | Threading | |||

| Material | Stainless steel | |||

| Air Flow | 2.5 ~ 3.5kg/cm2 (36~50psi) | |||

| Temperature | Máx.70ºC (158°F) | |||

| Pressure | Max.32kg/cm2 (455psi) | |||

| Hydraulic body test | Max.48kg/cm2 (682psi) | |||

a) PT, NPT and BSPT threads are available.

b) Bronze material is available, but the temperature and pressure must be modified.

INSTALATION

a) The single-acting valve has a spring. b) The double acting valve is springless, therefore it needs 2 air supply lines.

a) The fluid is water.

b) The O ring is easy to damage. A filter must be installed before the valve.

c) The speed of the hydraulic cylinder can be changed according to the water pressure.