FEATURES

- Valve controls pressure and temperature.

- Multi Spring for more precise proportional control.

- “Stellite welded" body seat and plug.

- Grinding to meet ANSI Class V seat leakage level (Control Valve Seat Leakage).

- Spring with shot-blasting process for improved service life.

- Stainless steel body and plug.

- Single seat and globe control valve.

AVAILABLE MODEL

VCM-1000F

VCM-1000S

VCM-1100F

VCM-1100S

SPECIFICATIONS

| Model Name |

Lineal | VCM-1000F(S) | VCM-1000S |

VOM-1000F | VOM-1000S |

|---|---|---|---|---|---|

| % equivalent

|

VCM-1100F(S) | VCM-1100S |

VOM-1100F | VOM-1100S | |

| Fluids | Steam, Industrial Water, Gas (N2), aire | ||||

| Size (mm) | 15A~40A(VCM-1100F : 15A~80A) | ||||

| Operation | Normally closed (NC) | Normally open (NO) | |||

| FInal Connection | Bridado | Roscado | Bridado | Roscado | |

| Material | Acero inoxidable, Tapón y Asiento: Estelitado (Soldadura) | ||||

| Flow Characteristics | Linear / Equal % | ||||

| Spring range | 0.2 ~ 1.0kg/cm2 (2.9~14.0psi) : KP Max.7 kg/cm2 0.4~1.2kg/cm2 (5.7~17.1psi) : KP Max.16 kg/cm2 0.8~2.4kg/cm2 (11~34.0psi) : KP Max.24 kg/cm2 |

||||

| Temperature | Máx.220°C (428°F) / Same: Máx.250°C (482°F) | ||||

| Presión | Max.32kg/cm2 (455psi) | ||||

| Seat type | Single seat | ||||

| Hydraulic body test | Max.48kg/cm2 (682psi) | ||||

a) JIS, DIN and ANSI standards are available.

b) (S) means SUS flange.

c) E/P positioner is available.

d) ⲔP means differential pressure. ⲔP = P1 – P2.

e) ⲔP for sizes 65A, 80A is Max. 4kg/cm2 (spring range 0.2~1.0kg/cm2)

UK Max. 18kg/cm2 (spring range 0.8~2.4kg/cm2)

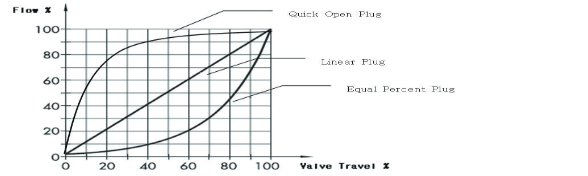

FLOW CHART

a) Shape of the plug.

b) The graph does not include real system variables.

c) In the actual installed flow characteristic, the Equivalent Percentage becomes more Linear and the Linear becomes more Quick Opening.

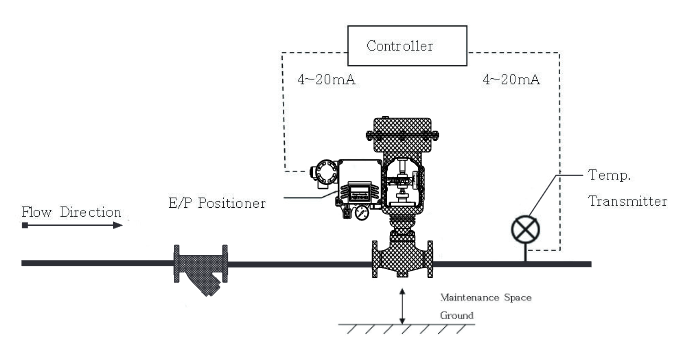

INSTALATION

a) The control valve must be connected with an E/P positioner or an I/P converter.

b) If the valve is purchased with an E/P positioner, it is supplied after setting the Zero and Range. However, when the user uses an I/P converter, the user must adjust the Zero and Range of the I/P converter.

c) To protect the valve, a filter must be installed before the valve.