FEATURES

- Valve reduces pressure.

- Diaphragm can respond quickly to pilot air supply and resist foreign material.

- The diaphragm has a longer service life than a metal plate or bellows and iseconomical.

- Easy installation and maintenance.

- Perfect sealing with the disc made of PTFE Carbon Graphite.

- The valve can be used not only in steam lines, but also in gas lines.

AVAILABLE MODELS

SRV-1100S

SRV-1100F

SRV-1100FS

SPECIFICATIONS

| Model's name |

SRV-1100S |

SRV-1100F | SRV-1100FS |

|---|---|---|---|

| Fluids | Steam, Industrial water, Gas (N2). | ||

| Size (mm) | 15A,20A,25A,40A,50A | ||

| Final connection | Threaded | Flanged (A105) | Flanged (SCS13) |

| Material | Body: Stainless steel / Diaphragm: PTFE / Disc: Carbon graphite PTFE. | ||

| Reduction ratio

|

1:1(15A,20A), 1:0.8(25A,40A,50A) | ||

| Temperature | Max.230ºC (446ºF) | ||

| Pressure | Max.15kg/cm2 (213 psi) | ||

| Hydraulic body test | Max.48kg/cm2 (683 psi) | ||

a) JIS, DIN and ANSI standards are available.

b) Size 32A is not available.

c) The reduction rate can be changed on the real line.

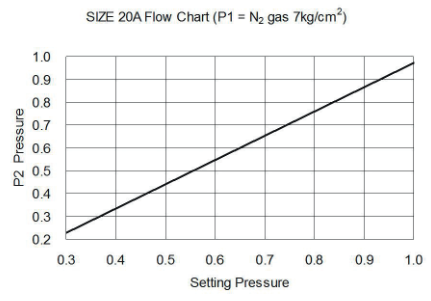

FLOW CHART

a) The inlet pressure is 7 kg/cm2.

b) Size 20A (Ratio 1:1), Size 25A (Ratio 1:0.8).

c) On the real line, data can be changed.

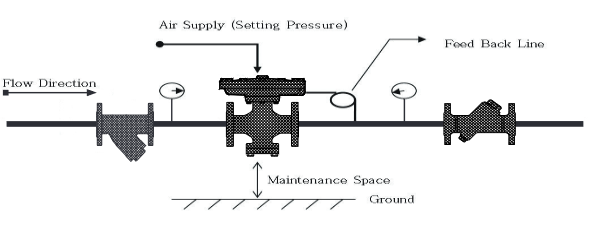

INSTALATION

a) Pilot air supply is set pressure.

b) Set pressure is supplied from an I/P converter or air regulator.

c) Because the turndown rate is changed in the actual line, the I/P converter or air regulator must be calibrated to obtain the required pressure at the second port.

d) A pressure gauge is installed to check the reduced pressure in the second port.

e) Complete flushing of pipes is required prior to valve installation.

f) The pressure regulating valve must be in a vertical position in horizontal pipes.

g) A check valve is installed to prevent reverse flow.

h) To protect the valve, a filter must be installed before the valve.

i) The feedback line should be spiral.