FEATURES

- Strainer filters out foreign materials in the pipe line.

- Y-shaped design to minimize pressure loss.

- All parts are made of stainless steel suitable for high temperatures and high pressures.

AVAILABLE MODELS

VST-500F

VST-500S

VST-500FS

SPECIFICATIONS

| Model Name |

SRV-1100S |

SRV-1100F | SRV-1100FS |

|---|---|---|---|

| Fluids | Steam, Industrial Water, Gas (N2). | ||

| Size (mm) | 15A,20A,25A,40A,50A | ||

| Final connection | Threaded | Flanged (A105) | Flanged (SCS13) |

| Material | Body: Stainless steel / Diaphragm: PTFE / Disc: Carbon graphite PTFE. | ||

| Reduction ratio |

1:1(15A,20A), 1:0.8(25A,40A,50A) | ||

| Temperature | Max.230ºC (446ºF) | ||

| Pressure | Max.15kg/cm2 (213 psi) | ||

| Hydraulic body test | Max.48kg/cm2 (683 psi) | ||

a) JIS, ANSI and DIN standards are available.

b) Various hole drilling rates are available.

c) Mesh is available.

d) Available for high pressure (JIS 30K).

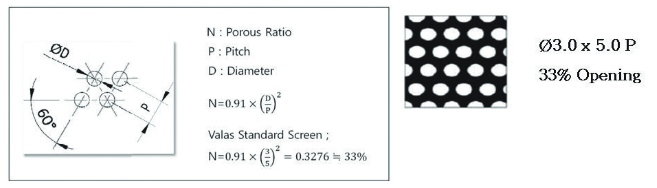

STANDARD PERFORATED SCREEN

a) A variety of hole drilling rates are available.

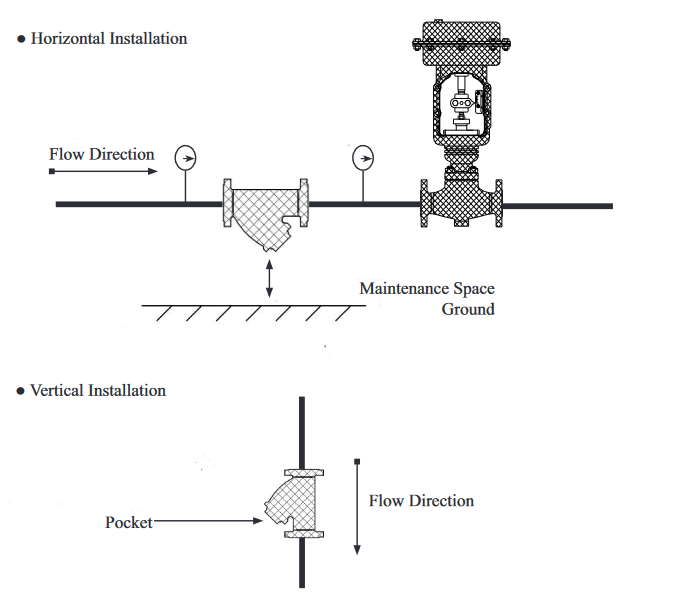

INSTALATION

a) It should be installed before the important valve.

b) In the steam line, a ball valve can be connected to the bag to drain condensation and prevent water impingement and foreign materials.

c) The direction of the filter arrow must be the same as the flow direction.

d) The line must have enough space to clean the filter.

e) If the pressure difference between both sides increases, the user must remove foreign materials from inside the filter.

f) It must be installed vertically on horizontal pipes and can also be installed on vertical pipes.

g) Especially in the steam line, the filter bag should be placed horizontally to avoid condensation buildup on the bag.

h) The filter in vertical pipes must be placed with the bag facing down.